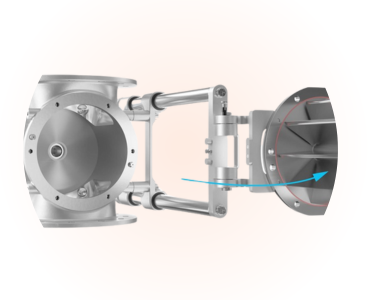

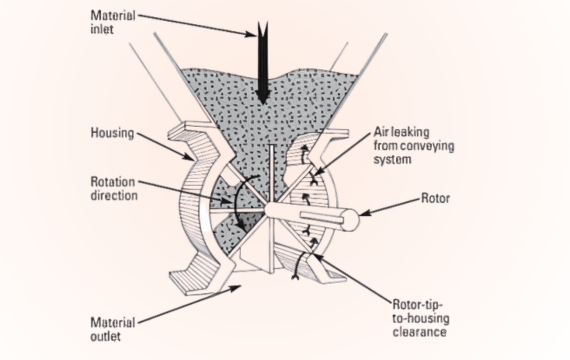

A Rotary Airlock Valve is a highly engineered device integral to pneumatic conveying and material handling systems, designed for efficient transfer of bulk materials such as powders, granules, and pellets between chambers with differing pressure levels. The valve consists of a rotating rotor with pockets that trap material and release it downstream, minimizing pressure fluctuations and preventing air leakage. This ensures consistent material flow and system integrity, making it ideal for applications in industries such as food processing, pharmaceuticals, chemicals, and cement. Its robust design supports diverse operational conditions, including abrasive materials and high-temperature environments, enhancing reliability and process efficiency.

The working principle of a Rotary Airlock Valve involves a rotor with evenly spaced vanes rotating inside a precision-machined housing. Bulk material enters the valve through the inlet, filling the rotor pockets. As the rotor turns, the material is discharged through the outlet, maintaining a consistent flow. The tight clearances between the rotor and housing minimize air leakage, preserving pressure differentials. Typically driven by a motor or gear reducer, rotary valves handle materials under various conditions, including abrasive, cohesive, or high-temperature environments.